Around 2023–2024, when cold therapy first became popular, there were a lot of inflatable tubs that looked the same.

Back then, just “holding air” for a day was enough to pass quality control. The world has changed a lot by 2026. The worldwide market is more mature now, and B2B customers like you are no longer just buying stock; you’re also putting money into the reputation of the company.

As a top inflatable cold plunge OEM maker, we know that the main difference in 2026 isn’t just the price; it’s how long the product lasts.

That’s why we’ve stopped using conventional air-check techniques and switched to Hydrostatic Submersion Testing, which is much more thorough.

What is Hydrostatic Submersion Testing? (And Why It Matters)

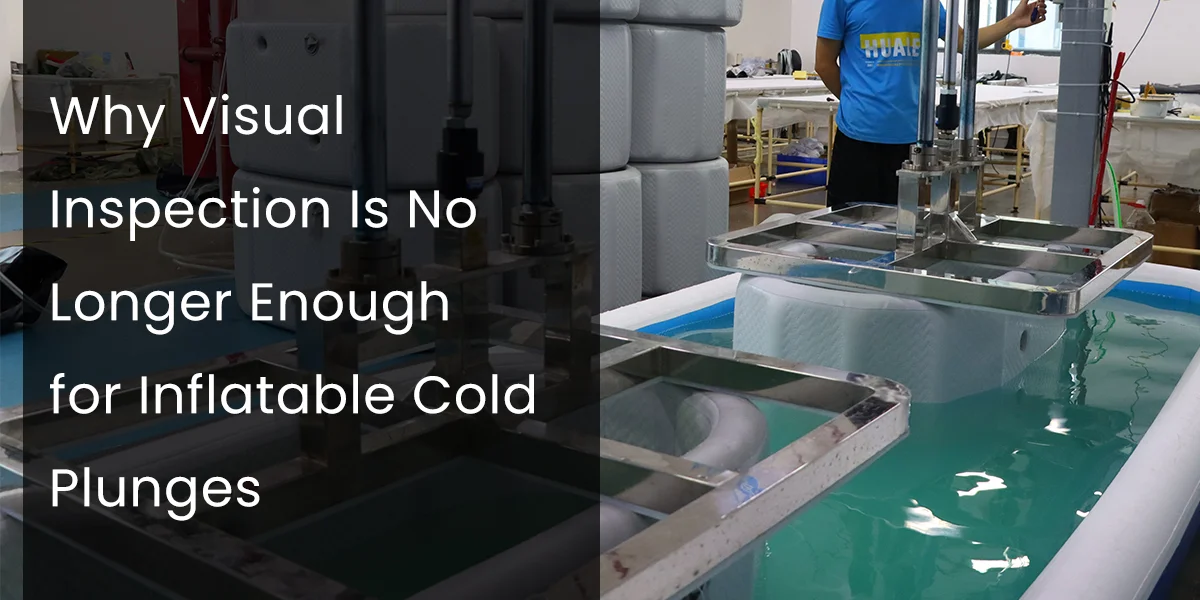

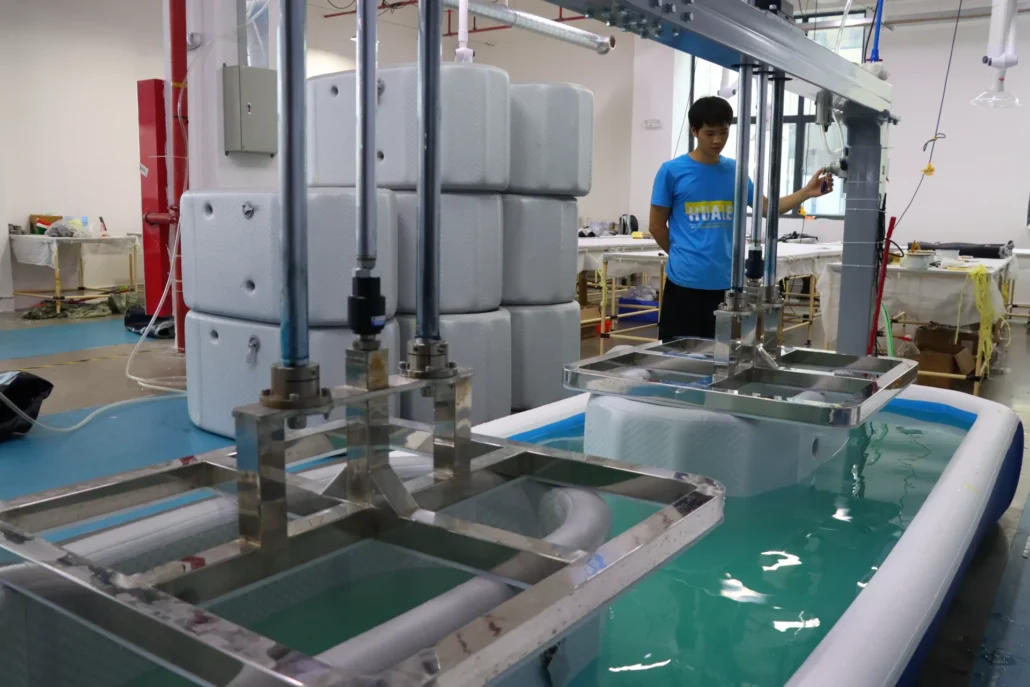

Look at the picture below that was taken right on our production floor. What you see is not just a cleaning process; it is the most difficult part of our Quality Control (QC) line.

During this operation, a custom-made metal gear is used to forcefully submerge finished inflatable ice baths underwater while they are at their highest PSI.

The Physics Behind the Bubbles

Why go to this trouble? The principle is simple but brutal.

- Air Pressure vs. Water Pressure: Putting the device in water makes the surroundings very different.

A “champagne trail” of small bubbles will form even if there is a tiny pinhole leak that can’t be seen with the naked eye or picked up by normal pressure gauges for more than 24 hours. - Seam Stress Testing: The water pressure acts uniformly on the Drop-Stitch material, testing the integrity of the double-layer fusion seams

The “Silent Killer” of Ice Bath Brands: Slow Leaks

According to data from 2025, 68% of warranty claims for inflatable recovery gear were for “slow leaks” that showed up 2–3 months after the item was bought.

In the competitive landscape of 2026, a customer waking up to a semi-deflated tub isn’t just a refund; it’s a negative viral review. Basic static testing (keeping the tub inflated on a shelf) doesn’t find:

- Micro-porosity: Problems with the PVC material itself.

- Valve Seepage: Very small spaces in the installation of the Bravo valve.

Before the product is even put in a box, our Submersion Protocol gets rid of this risk.

How We Optimize Quality Control for 2026 Trends

The inflatable business has changed. People who buy “Cold Plunge 2.0” nowadays want it to last a long time and be environmentally friendly. This is how our factory remains ahead:

Zero-Tolerance for Micro-Leaks

We don’t only inspect things by eye; we test them in batches. If bubbles show up, the unit is immediately discarded. This guarantees that the Air Retention Rate of the goods we send out is higher than 99.8% over a week.

Integration with Eco-Materials

As the industry shifts towards TPU (Thermoplastic Polyurethane) and biodegradable composites in 2026, material sensitivity changes. Submersion testing is the only safe way to stress-test these newer, eco-friendly materials without damaging their structural integrity.

The Human Element

As seen in the photo, our specialized QC technicians monitor the water tank visually.

AI cameras are employed in other portions of our line, but the trained human eye is still the greatest way to see the subtle refraction of a bubble stream in rough water.

Partner with a Factory That Prioritizes “Invisible Quality”

It’s hard to tell the truth when every product spec sheet looks the same.

You don’t just buy PVC and adhesive when you get your supplies from us. You are buying the peace of mind that your product has passed the “dunk tank.”

You are buying the peace of mind that your end-user’s tub will stay solid, stiff, and ready when they fill it up in the morning.

Want to improve the quality of your supply chain to 2026 levels? Contact Huale Now!