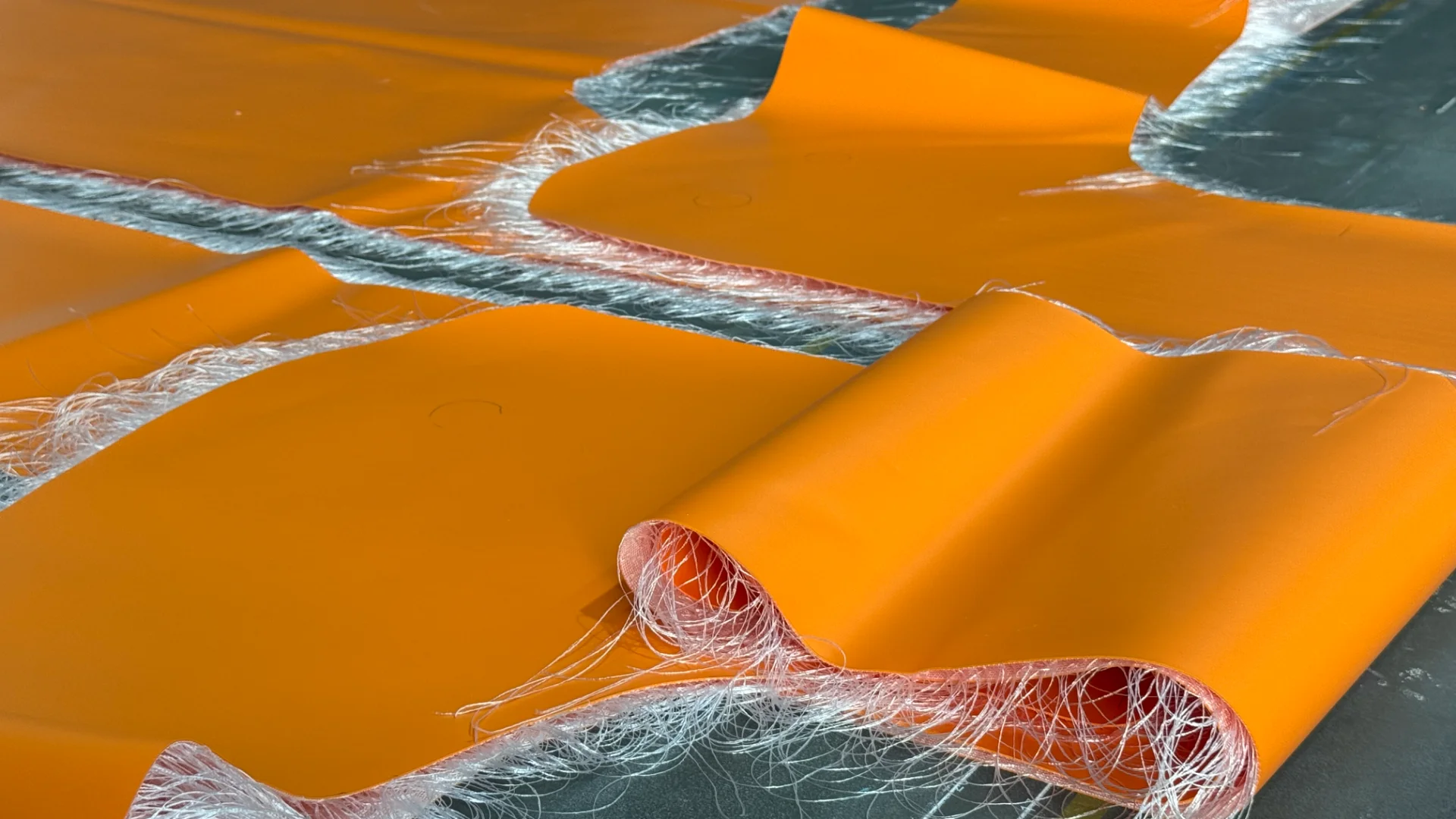

The Foundation of Quality: Advanced Drop-Stitch Technology

- Ultra-High Density Core

- Lightweight & Rigid Construction

- Available in Woven & Knitted Styles

Why It Matters for Your Business

High-Tensile Strength Core

Our drop-stitch core ensures your boards can be inflated to 20+ PSI without deformation.

Fusion & Double Layer Compatibility

Whether you choose Single Layer, Double Layer, or Fusion Tech, our material guarantees long-lasting adhesion.

Uniform Surface & Flatness

Perfect surface for printing and applying PVC layers, ensuring a flawless cosmetic finish for your brand.

| Specification | Knitted Drop Stitch (Standard) | Woven Drop Stitch (Advanced) |

|---|---|---|

| Structure Type | Linear Knitting Technology | Matrix Woven Technology |

| Weight (Base Fabric) | Standard (approx. 2.8kg/sqm) | Ultra-Light (approx. 1.9kg/sqm) |

| Tensile Strength | High | Extreme (High Density) |

| Max Pressure | Up to 15-18 PSI | Up to 25+ PSI |

| Rigidity/Stiffness | Excellent | Superior (Minimal Flex) |

| Best Application | Yoga Mats, All-Round SUPs | Racing Boards, Touring SUPs, Docks |

How We Turn Your Product Idea into Reality

01

Client Request

02

Idea & Design Direction

03

2D/3D Rendering

04

Quotation

05

Sampling / Prototyping

06

Client Confirmation

07

Tooling & Setup

08

Mass Production

09

Final Inspection

10

Delivery

Q1: What is the main difference between Woven and Knitted Drop Stitch material?

Knitted Drop Stitch is the industry standard, offering a comfortable balance of durability and cost. It uses a knitting process to connect layers. Woven Drop Stitch is our premium offering. By weaving internal yarns into a tighter matrix, it creates a material that is significantly lighter (approx. 20% less weight) and stiffer. It supports higher inflation pressures (20+ PSI), making it ideal for high-performance racing SUPs.

Q2: Can Huale customize the thickness and dimensions for my brand?

Yes, as a direct manufacturer, Huale offers full OEM customization. We produce Drop Stitch material in standard thicknesses of 4″ (10cm), 6″ (15cm), and 8″ (20cm), as well as custom specifications up to 35cm for specialized floating docks. We also support custom widths and color variations to match your brand guidelines.

Q3: How do you ensure the durability and airtightness of the material?

Quality is paramount at Huale. Every roll of material undergoes rigorous testing, including tensile strength tests, UV resistance analysis, and a 48-hour inflation test to ensure zero leakage. Our Fusion Technology (Double Layer) minimizes glue usage while maximizing structural integrity, preventing delamination even under harsh conditions.

Q4: What products can be manufactured using your Drop Stitch fabric?

Our material is versatile and engineered for various water sports and industrial applications. It is widely used for Inflatable Stand Up Paddle Boards (SUPs), Gymnastics Air Tracks, Floating Docks, Rescue Rafts, Kayak floors, and portable camping mattresses.

Q5: Can I order a sample to test the rigidity before a bulk order?

Absolutely. We encourage our B2B partners to test our quality first. We can provide A4-sized material swatches or a full sample product (e.g., a sample board) for your engineering team to evaluate. Contact our sales team to request your sample kit.

Q6: What is your typical production lead time for bulk orders?

For standard Drop Stitch material rolls, our lead time is typically 15-20 days. For finished OEM products (like customized SUPs), production usually takes 30-45 days depending on the order quantity and customization complexity. We offer flexible shipping solutions to meet your seasonal launch deadlines.

Talk To Our Expert

Your information will be kept strictly confidential.

We will contact you within 1 hour. Please pay attention to the email with the [email protected]