Inflatable Manufacturing Process

& Quality Control System

Dedicated teams collaborate at our state-of-the-art facility to guarantee that each inflatable product we distribute meets the most stringent quality, durability, and performance standards.

Observe the manner in which we instill confidence in all of our products

Our Manufacturing Departments

1.Research & Development (R&D) and Design

- Core Mission: Our research and development team is at the forefront of the development of innovative materials, construction methods, and product designs.

They collaborate directly with you to transform your custom conceptions for air tracks and paddle boards into precise, production-ready specifications. - Resolving Your Complaints: Expert execution is necessary to realize your distinctive vision.

We ensure that your custom designs are not only innovative but also structurally sound and manufacturable, thereby preventing costly design defects.

2.Raw Material Sourcing & Warehousing

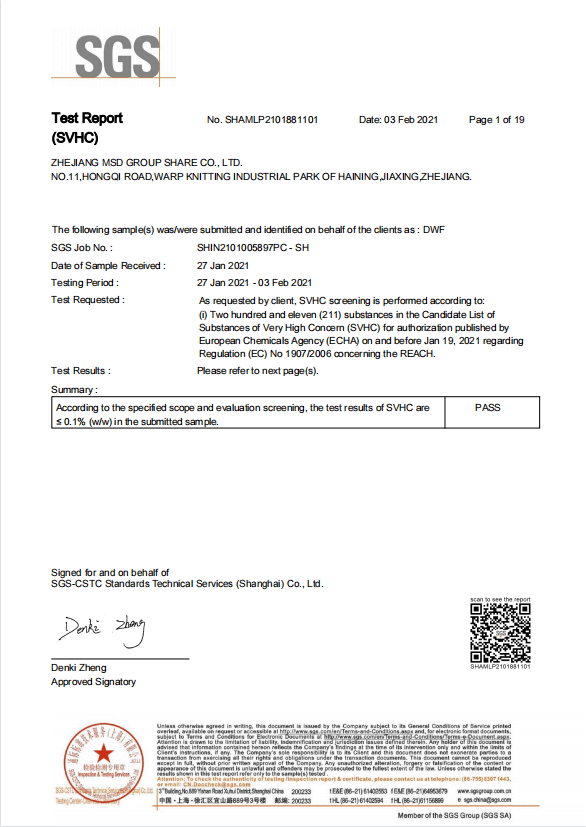

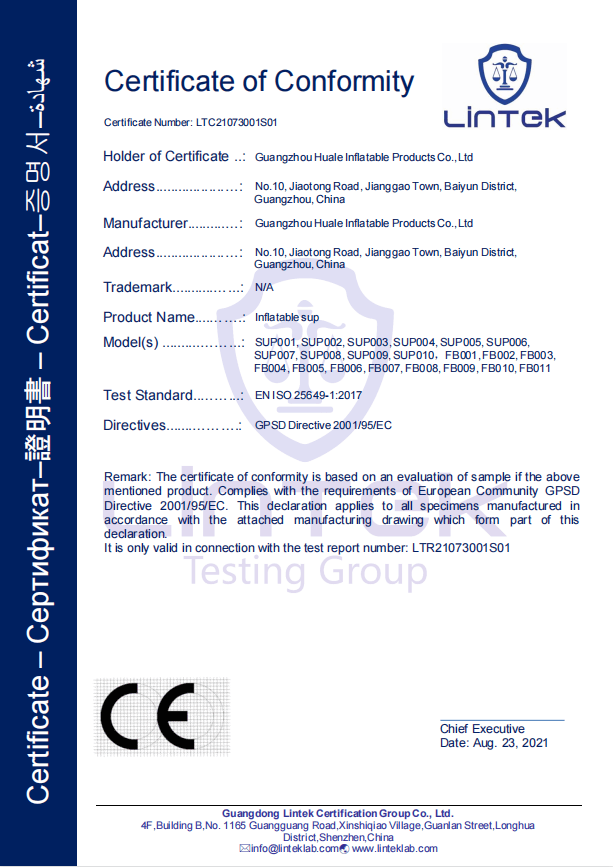

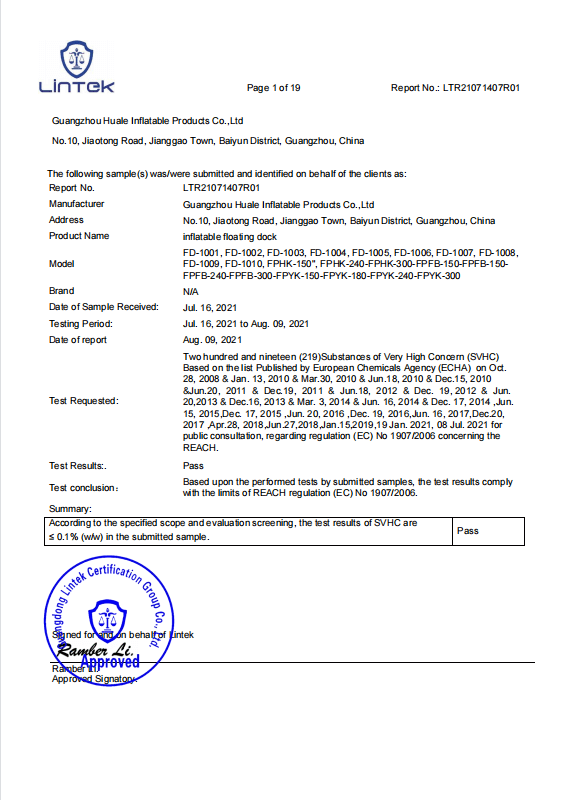

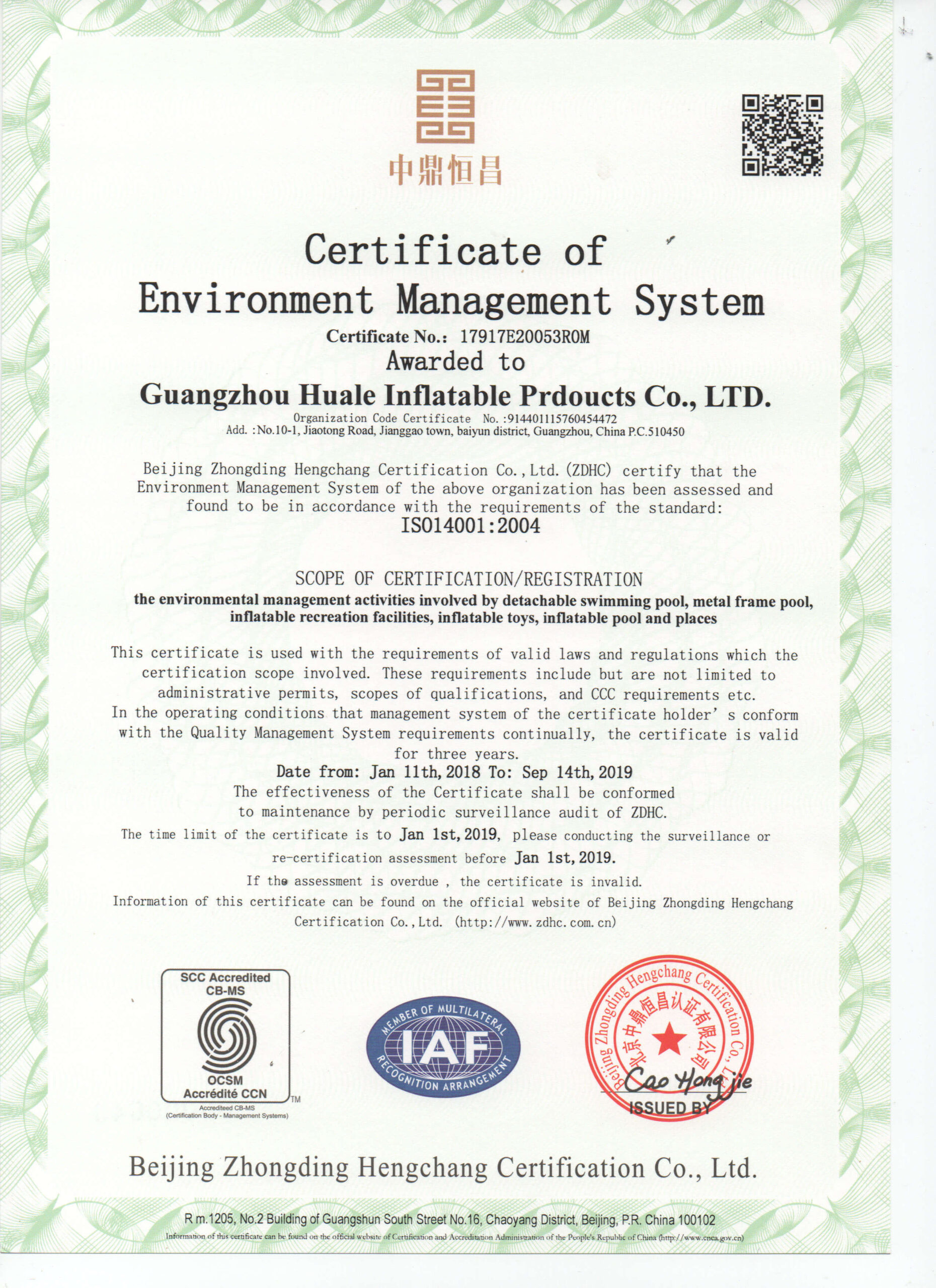

- Core Mission: The department is accountable for the procurement, testing, and supervision of all raw materials, including our premium Double Wall Fabric (DWF) and PVC. Our warehouse is meticulously organized to guarantee a consistent and prepared supply for production.

- Resolving Your Complaints: The materials are the foundation of product durability.

We ensure that your final product is constructed to last and functions as anticipated by conducting a thorough examination of all incoming materials, thereby reducing the likelihood of substandard quality.

3. Cutting & Printing Department

- Core Objective: We utilize sophisticated CNC machines to accurately cut all material patterns.

Before the assembly process, our printing division applies your custom logos and graphics using high-fidelity, UV-resistant pigments. - Resolving Your Complaints: Your brand is negatively impacted by inconsistent shapes and diminishing logos.

Our sophisticated printing technology guarantees that your branding remains sharp and vibrant, while our precision cutting guarantees that every product is identical.

4. Assembly & Gluing Department

- Core Mission: This is the location where expert technicians meticulously hand-assemble and affix each product.

Our teams are instructed in the utilization of sophisticated seam-sealing and bonding methods to construct structures that are both hermetic and durable.

Resolving Your Complaints: The primary cause of product failure is air leakage.

Our emphasis on expert craftsmanship and established adhesive methods guarantees the highest level of airtightness and seam strength, thereby significantly reducing defect rates.

5. Quality Control (QC) & Inflation Testing

- Core Mission: Our independent quality control team conducts thorough inspections at each stage.

The 24-hour inflation test is the most critical stage, during which each product is inflated to a specific pressure to detect any leaks or imperfections before packing. - Resolving Your Complaints: It is expensive and detrimental to one’s reputation to receive defective products.

Our multi-stage quality control process, particularly the mandatory 24-hour inflation test, guarantees that the products you receive are flawless and prepared for your consumers.

6. Packaging & Logistics Department

- Core Mission: Our primary objective is to develop and execute effective packaging solutions that safeguard your products during transportation.

This team is responsible for the coordination of shipping partners and the management of order fulfillment to guarantee the timely and dependable dispatch of goods worldwide. - Resolving Your Complaints: Your business may be rendered inoperable by shipping delays and damage.

We ensure that your orders arrive on time by managing logistics and providing secure packaging to prevent transit-related issues.

Trusted by World Class Brands

Your Partner for Reliable, High-Volume Manufacturing

Every step is engineered to ensure consistency and quality, from the meticulous procurement of materials to the mandatory 24-hour inflation test.

We provide our B2B partners with the ability to manage orders of any size, transparent communication, and manufacturing reliability.

Experience the assurance of collaborating with a genuine manufacturing expert by forming a partnership with us.

1. Can we visit your factory in person or schedule a virtual tour?

Certainly, we encourage our B2B stakeholders to observe our operations in person.

We provide comprehensive virtual factory excursions via video call for your convenience, or you may arrange an in-person visit to our facility.

This enables you to interact with our team and observe our dedication to quality from any location on Earth.

Please reach out to us to schedule a tour.

2. How do you ensure the quality and consistency of raw materials like DWF?

Our Raw Material Sourcing department exclusively collaborates with certified suppliers.

Before being approved for production, each batch of material, particularly our core Double Wall Fabric (DWF), is subjected to stringent in-house testing for tensile strength, air-tightness, and UV resistance.

This ensures that each product is built upon a solid foundation of quality.

3. What is your standard procedure for quality control on finished products?

Our quality control procedure is a multi-stage process.

Every inflatable product, regardless of whether it is an air track or a paddleboard, is subjected to a mandatory 24-hour inflation test after assembly.

The product is then inflated to the recommended pressure.

Our quality control team conducts a meticulous inspection of the product during this time to identify any cosmetic defects, seam imperfections, or pressure loss.

No product is packaged until it has successfully completed this final, critical evaluation.

4. How do you handle custom designs and client logos?

Our R&D and Design department collaborates with you to finalize your custom specifications.

The designs are forwarded to our Cutting & Printing department upon approval.

We guarantee the sharpness, vibrancy, and durability of all logos and graphics by employing high-quality, UV-resistant inks and precision CNC machines for precise cutting.

5. What makes your manufacturing process reliable for large B2B orders?

Reliability for our B2B partners is built on three pillars:

1) Stable Supply Chain: Our strong relationships with material suppliers ensure a consistent flow of raw materials.

2) Scalable Production: Our organized departments and skilled workforce can scale to meet high-volume orders.

3) Rigorous QC: Our strict quality control at every step minimizes defect rates, ensuring the entire batch meets your standards. This combination guarantees consistent quality, even for the largest orders.

Talk To Our Expert

Your information will be kept strictly confidential.

We will contact you within 1 hour. Please pay attention to the email with the [email protected]