Introduction: The “Glued Board” Era is Over

If we look back at the paddle board market in 2020, manual gluing was the norm. It was messy, heavy, and frankly, a ticking time bomb for warranty claims.

Fast forward to 2026. If you are a brand owner still sourcing hand-glued boards, you are taking a massive risk. The industry standard has shifted. The top-tier inflatable paddle board manufacturers have moved to a “Fusion-First” approach.

Why? Because in a competitive market, you cannot afford returns caused by seam leaks in the summer heat.

At Huale Inflatable, we have fully transitioned our production lines to utilize High Frequency (HF) Welding and Heat Fusion technologies. Let’s break down the physics of why these boards are lighter, stronger, and virtually indestructible.

Technology 1: Heat Fusion (The “Skin” of the Board)

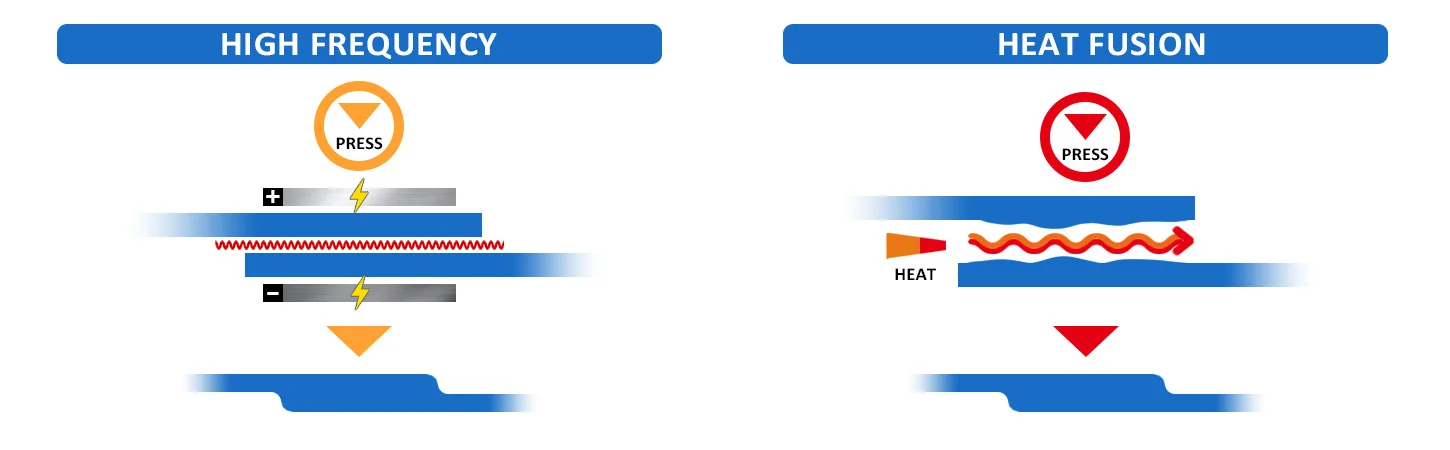

Look at the right side of the diagram above. This is Heat Fusion (often called MSL or Machine Lamination).

In the old days, the drop-stitch core was glued to the outer PVC layer. This glue added unnecessary weight—sometimes up to 2kg per board—and created a weak point where bubbles could form.

How It Works in 2026

Instead of cold glue, we use a machine that applies precise heat and pressure to fuse the raw drop-stitch material directly to the high-density PVC shell. It essentially turns two layers into a single, inseparable material.

The B2B Advantage

- 20% Lighter: By eliminating the liquid adhesive layer, shipping costs drop significantly.

- Cosmetic Perfection: No glue marks, no wrinkles. The surface is perfectly smooth, which is ideal for high-quality digital printing of your brand’s graphics.

- Higher Stiffness: The fused structure creates a stiffer “skin,” allowing the board to perform closer to a hard epoxy board.The fused structure creates a stiffer “skin,” allowing the board to perform closer to a hard epoxy board.

Technical Note: This process creates a bond that is actually stronger than the material itself, significantly reducing delamination risks cited in standard polymer welding studies

Technology 2: High Frequency Welding (The “Seams” of the Board)

Now, look at the left side of the diagram labeled “High Frequency.” This is where the magic happens for the rails (the sides of the board).

The rails are the #1 failure point on any inflatable. Traditional boards use glue to hold the rails together. Over time, UV exposure and high temperatures (like leaving a board on a sunny beach) break down the chemical bonds in glue. The result? Leaks.

The Electromagnetic Solution

High Frequency Welding (RF Welding) doesn’t use heat from the outside; it uses electromagnetic energy to excite the molecules within the PVC. This causes the two layers of PVC to melt and flow into each other from the inside out.

As verified by experts in materials joining technology, this creates a hermetic seal. It’s not two pieces stuck together; it is now one continuous piece of PVC.

Why Warranties Love HF Welding

For our OEM partners, HF Welding is a profit saver.

- Zero Leaks: The bond is permanent. It does not degrade over time.

- Heat Resistance: These seams can withstand much higher temperatures than glued seams, making them perfect for markets like Florida, Australia, and Southeast Asia.

- Eco-Friendly: No volatile solvents or glues means a cleaner manufacturing process, aligning with 2026’s strict environmental compliance.

Comparing the ROI: Glued vs. Fused

For a distributor, the initial cost of a glued board might look cheaper. But let’s look at the math of the supply chain reliability.

| Feature | Hand Glued (Old Tech) | HF Welding + Heat Fusion (Huale Tech) |

|---|---|---|

| Lifespan | 2-3 Years | 5-7+ Years |

| Weight | Heavy (Glue adds mass) | Ultra-Lightweight |

| Leak Risk | High (especially in heat) | Near Zero |

| Finish | Often inconsistent | Machine Precision |

Conclusion: Future-Proof Your Inventory

In 2026, customers are educated. They ask about “Double Layer Fusion” and “Welded Rails.”

Don’t let your brand reputation hang on a layer of cheap glue. By partnering with a factory that utilizes High Frequency and Heat Fusion, you aren’t just buying a paddle board; you are investing in a zero-defect reputation.

Ready to upgrade your product line?

Huale Inflatable offers full OEM services using these advanced technologies. Whether you need a racing SUP or a durable Inflatable Dog Ramp, we manufacture with the same military-grade precision.