In the competitive landscape of 2026, the battle for profit margins isn’t just won on the production floor—it’s won in the shipping container.

For years, the industry standard was manual labor. Workers would deflate air tracks and roll them by hand. The result? Inconsistent roll sizes, “bloated” packaging, and wasted space inside cartons. In an era where global logistics costs have stabilized but remain high, shipping “air” is a luxury no B2B distributor can afford.

At Huale Inflatable, we have phased out manual packing for our premium lines. We have upgraded to fully Automated Rolling & Packing Systems. Let’s look at the science behind why this machine is your new best friend.

The Mechanics of “Compression Packing” Technology

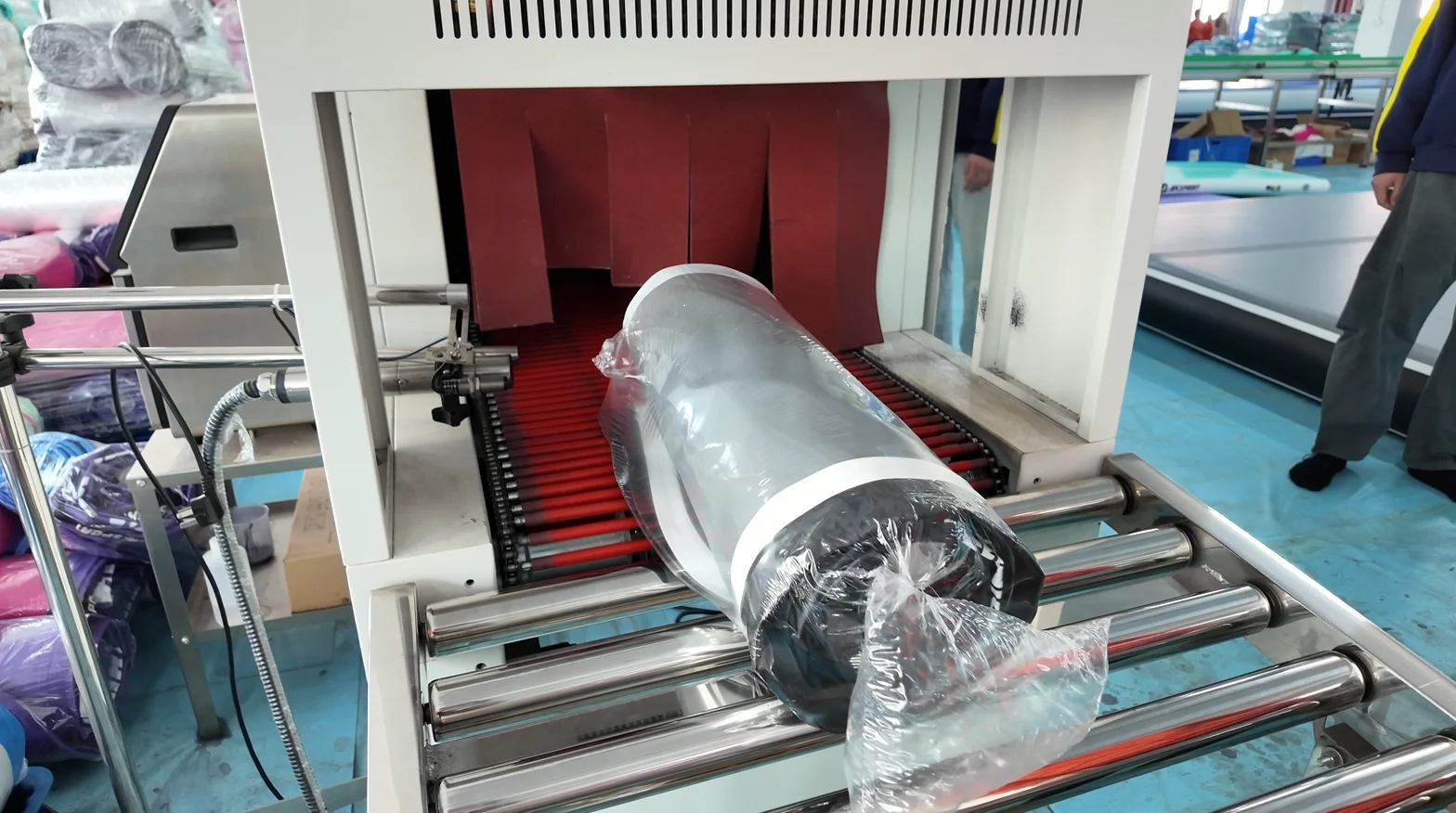

As you can see from our factory floor photos, the process is entirely hands-off. Once the air track is deflated and laid flat on the conveyor, the machine takes over.

The “15% Volume Reduction” Rule

Human strength has limits. No matter how hard a worker tries, they cannot roll a 10cm or 20cm thick drop-stitch mat as tightly as a hydraulic motor.

Our machine applies constant, calibrated pressure throughout the rolling process. This results in a cylinder diameter that is consistently 15% to 20% smaller than manual rolling. In logistics terms, this significantly improves your dimensional weight pricing.

- Manual Roll: Looser layers, requires a larger box.

- Machine Roll: Dense layers, fits in a compact box.

Integrated Hygiene Protection

Look closely at the machinery. As the mat is rolled, a protective film is automatically applied between the layers and around the exterior.

This ensures that when your customer unboxes the product, it is pristine—free from dust, fingerprints, or warehouse debris.

The ROI Calculation: Why CBM Matters More Than Ever

Why does a tighter roll matter? Because in 2026, ocean freight is calculated by CBM (Cubic Meters).

Let’s do the math on a typical 40HQ container order:

- Manual Rolling: Average box volume 0.08 CBM -> Fits ~850 Units per container.

- Huale Machine Rolling: Optimized volume 0.065 CBM -> Fits ~1050 Units per container.

The Result: By optimizing the packaging, you are essentially shipping 200 units “for free” compared to the old method. This efficiency aligns perfectly with modern supply chain sustainability goals by reducing the carbon footprint per unit.

Consistency for Amazon FBA & Retail Shelves

For our partners selling on Amazon or in physical retail stores, consistency is key.

Manual rolling leads to “box bulging,” where boxes arrive distorted and are rejected by automated warehousing systems.

Huale’s machine-rolled air tracks fit perfectly into standard, durable cartons every single time. This reduces the risk of storage fees and returns due to packaging damage.

Conclusion: Upgrade Your Supply Chain

In 2026, a paddle board or air track manufacturer shouldn’t just be an expert in PVC; they need to be an expert in logistics.

Don’t let inefficient packing eat into your margins. Partner with a factory that invests in automation to save you money.

Ready to Optimize Your Shipments? See the difference a tighter roll makes. Request a packing video or a quote for our machine-rolled air tracks today.